he market environment of buffing and polishing wheel manufacturers is getting worse, because the industry profit margin is extremely low. So the rising labor cost became their greatest concern, Hightex serial automatic spiral sewing machines just came under this background.

Many buffing wheels manufacturers are searching for machines not only to make the production process more automation, but also to lower the production costs (reducing number of employees). We devote ourselves to develop highly automated industrial sewing equipment base on the concept of "One-Worker-Multiple-Machine (OWMM)", for maximizing efficiency and controlling costs.

204-370BP Heavy duty automatic polishing wheels sewing machine with spiral sewing device

It is advanced spiral sewing equipment for high end buffing wheel manufacturers. Features in triple feed sewing machine, needle protector (avoid needle bend or break when hit the knots of sisal wheels). Ideal for 1 / 2 "to 3/4" thick buffing wheels and polishing wheels made of cotton, sisal, flannel and Denim, max. diameter of wheel is 630 mm. One worker can operate 2-3 sewing units at same time.

Click here for video

733BP Extra heavy duty automatic buffing wheel sewing machine for thick Sisal buffing wheels

It is heaviest automatic sewing equipment for sewing buffing wheels and polishing wheels. Features in extremely high needle penetration force, walking foot feed mechanism, 38 mm presser foot lift and 420 mm working area. Ideal for 1 / 2 "to 1-1/4" thick buffing wheels made of stiff sisal fibers, max. diameter of wheel is 830 mm. One worker can operate 2-3 sewing units at same time.

Click here for video

733-30BP Extra heavy duty long arm industrial sewing machine for large size (diameter) buffing wheel and polishing wheels

This heavy duty industrial sewing machine arm has been extended to give 760mm clearance, which is very useful when sewing large buffing wheel and polishing wheels. Features in walking foot feed mechanism, 32 mm presser foot lift. Ideal for 1 / 2 "to 1" thick buffing wheels and polishing wheels made of cotton, sisal, flannel and Denim, max. diameter of wheel is 850 mm. One worker can operate 2-3 sewing units at same time.

Click here for video

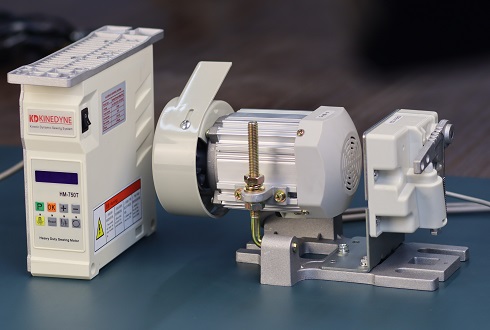

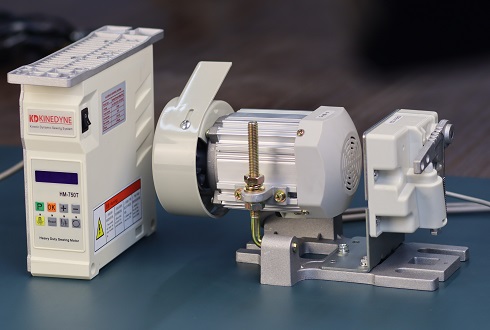

Kinedyne HM-750T the most powerful energy saving servo motor for heavy duty industrial sewing machines

A super powerful, quiet and reliable energy saving servo motor perfect for extra heavy duty webbing sewing machine. This high performance servo motor can save 60-80% electricity and improve 20-40% efficiency of the harness sewing machines. Usually the cost of servo motor can be recovered within 2-3 years by saving money on electricity. However the advantage of time savings and labor cost saving will make the actual return on investment faster.

Click here for 3D video

Click here for DEMO video

If you have any questions or concerns, please feel free to contact us at info@automatic-sewing.com, thank you!